Gas Diffusion and Dialysis

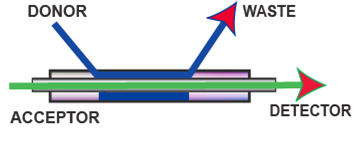

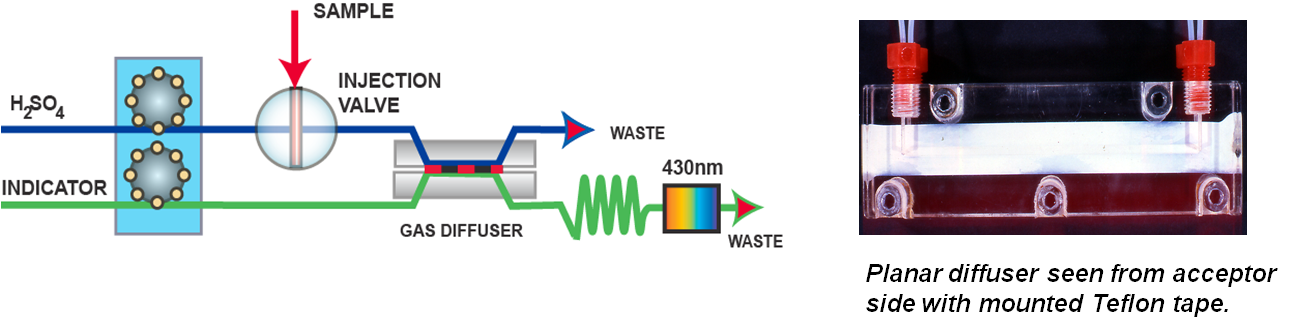

Initially introduced by Skeggs for the AutoAnalyzer sytem dialysis, the planar two plate diffusers found application mainly for flow based gas diffusion techniques. The device comprises two identical plates with engraved grooves, forming the channels, membrane and clamps or screws that held the assembled sandwich together.

Throughout the years the size (and channel volumes) decreased gradually so that for cFI applications the diffusion path was reduced to 15 cm length. With advent of pFI the size of the device is now reduced so that the diffusion path is only 2 cm long and 2 mm wide (1.2.35.). For gas/liquid separations, hydrophobic membranes made of porous Teflon® orpolypropylene are most widely used. When interposed between donor and acceptorstream they form a barrier that can be visualized as an “air gap” since they typicallycomprise up to 50% air trapped in the porous structure. For solvent extraction, porous Teflon® membranes have been used successfully in a phase separator, since its hydrophobic pores allow only the organic phase to pass. For dialysis, hydrophilic membranes with controlled size pores, ion exchange sites or homogenous films have been used.

Membranes can also be used as sampling devices. Global FIA. Porous tubing made of Teflon© has also been used in FI applications. Yet fabrication of this device requires skill and careful handling.

Literature:

H. Baadenhuijsen & H.E.H. Seuren-Jacobs, Clin. Chem. 25, 443, (1979)

M. D. Luque de Castro & I. Papaefstathiou, TRAC, 17, 41, (1998)

M.D. Luque de Castro , Membrane Based Separation Techniques, Dialysis, Gas Diffusion and Pervaporation.

Ch 8 in S. D. Kolev, I. McKelvie, Ed. Advances in FIA and Related Techniques. Elsevier , Amsterdam 2008

1.3.15.